Stock control with Orderwise

Looking for a high-performing stock management tool to accelerate operations? Discover the power of our stock-centric ERP solution.

To boost operations to new heights, retailer Leon Paul implemented Orderwise to revamp their purchasing and sales, right through to order handling and despatch.

Our high-performing stock management software is built to improve operations for complex wholesale, distribution and retail environments. Easily incorporate vital industry compliance into your workflow and speed up your pick, pack and ship processes with heightened accuracy.

With end-to-end stock visibility in real-time, our effective stock control system helps businesses to deliver more accurate reporting whilst reaping the rewards of improved stock performance.

As a stock-centric solution, OrderWise is built to handle even the most complex of stock requirements. Download the brochure to discover:

Orderwise software for stock control enables you to streamline daily stock operations with a scalable solution that allows sustainable business growth and evolution. Harnessing data from your sales and operations, gain accurate insights and simplify your finance operations, maintaining optimised purchasing and selling quantities year-on-year.

Whether you need a stock or inventory system to manage your entire operation or to help with certain elements of your stock, Orderwise software for stock management brings your operations back in order.

Track and verify items for your industry’s compliance standards.

Achieve rapid order fulfilment across all your warehouse sites.

Enhance workflows to realise sales potential and maximise opportunities.

Leverage 200+ reports to analyse all aspects of your operations.

Integrate with 60+ couriers for automatic operations and EDI.

Create stylish, responsive and integrated B2B and B2C websites.

Future-proof your growth with next-generation technology.

Control supply chains and make decisions with confidence.

Gain structured, streamlined handling of your returns.

Pick orders faster and more accurately with HHTs.

Manage stock components, from simple bundles to multi-level BOMs.

Track business performance with 300+ KPI displays.

Stock control itself is achieved by combining all the practices you need to effectively manage your inventory. Solving workplace dilemmas can be made easy for businesses of all sizes by managing your stock in the right way.

From organising orders, raw materials and storing products, to tracking and crunching numbers from receipt to despatch, the right stock control software can draw all of your specific stock management tasks together into one system. Users can gain a clearer picture of their stock operations and complete management tasks more accurately and efficiently.

A stock management system is the collective term for the systems, processes, and procedures that let your business stay informed and active regarding your stock. This includes both the stock you have physical access to, how many individual items you have, which specific variants are available, where on your premises they are being kept, as well as stock that is on order, the dates it is due to come in, and the spaces in your facilities set aside for their arrival.

Stock management is the systems you have in place to both keep all that information organised, and the processes to take action when that information tells you something important about your overall stock situation.

Stock management is improved with more information, more automation, and more speed. More information means additional details about every stage of your stock’s journey.

From your supplier’s premises, to their courier, to your warehouse, your racking, your pickers, and finally your customer’s doorstep. It also means more information about the stock itself, such as serial numbers to expiry dates, variant colours, and more. More automation means more alerts. Tailored messages that are triggered to send to you in specific circumstances that you need to be aware of. More speed means that all these things can happen faster. All this information and automation needs to be delivered in an easy-to-understand and easy-to-control fashion. This allows your business to act faster, respond quicker, and take advantage of new situations ahead of the competition.

High-quality stock management is vital for any business. At the most basic level, it can be the difference between retaining a satisfied customer/client or losing one who becomes disillusioned when a promised item turns out to be delayed or unavailable.

The better your stock management, the less likely the latter scenario becomes. The more advanced reasoning is that good stock management gives you the information you need to understand your business’s current situation. This empowers better decisions, faster responses to change, and more advantageous manoeuvring. If you can manage your stock well, you can satisfy your customers faster, stay abreast of market shifts, and respond with more agility. Good stock management makes you more able to do more business.

A stock control system plays a crucial role in the efficient and effective management of inventory within a warehouse. It empowers businesses to streamline their operations, maintain accurate stock levels, and optimise overall warehouse performance.

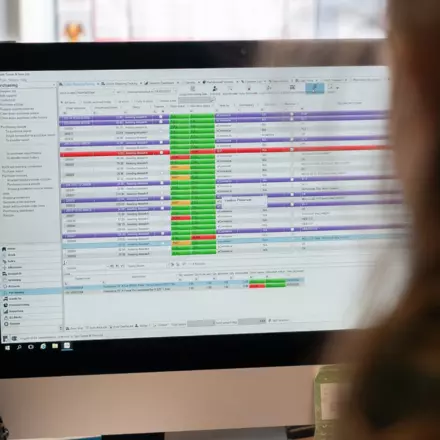

By utilizing advanced technologies such as barcode scanning, RFID tagging, or automated data capture, the system allows for real-time monitoring and tracking of stock movements. This real-time visibility enables warehouse managers to have an up-to-date view of inventory levels, facilitating better decision-making in purchasing, production planning, and order fulfillment processes.

By reducing the time taken to locate items, pickers can increase their productivity and fulfill orders more efficiently. The system can also prioritise orders based on various factors such as delivery deadlines or product priority, ensuring timely and accurate order fulfillment.

Looking for a high-performing stock management tool to accelerate operations? Discover the power of our stock-centric ERP solution.

Addressing the UK's returns crisis. Uncover the staggering financial and environmental impact of excessive returns.

Hear industry experts discuss the challenges currently being faced across global supply chains and how to stay on top of stock management.