The manufacturing landscape in Britain

A story of innovation

Britain, the birthplace of the Industrial Revolution - a historical legacy that still shines today, especially in high-tech sectors like aerospace. Around 2.6 million people are directly involved in UK manufacturing, and in 2023, British manufacturers proudly sold goods worth an astonishing £224 billion.

Reaching for the skies

In the world of aerospace manufacturing, Britain is no slouch, standing tall in second place on the global stage. Think helicopter parts and even spacecraft. Despite some rough patches, especially around the 2008 financial crash, our manufacturing legacy remains a point of pride.

Consistent growth in changing times

While manufacturing's role in our economic story has been shrinking, the amount of goods we make has been steadily growing at about 1.4% per year since way back in 1948. Surprisingly, manufacturing is still responsible for 44% of the things we ship overseas.

Embracing innovation in a new era

British manufacturers aren't stuck in the past. They're all about new technology and innovation. Automation, artificial intelligence, and the "fourth industrial revolution" are our new tools to boost productivity and streamline processes. This is us evolving with the times, just like the mature Western economies do.

Global production moves and staying competitive

Like other advanced economies, we've seen manufacturing jobs hop on planes to the Far East. But here's the twist: not everything has gone to China. Skilled, high-tech work is still a strong suit right here in the UK.

Skills shortage

Now, here come the hurdles. British manufacturers are facing the classic trio: productivity hiccups, a shortage of skilled workers, and some Brexit-related headaches. The "skills gap" is a big deal, especially for the small and medium-sized manufacturers. In fact, a hefty 42% of manufacturers say it's their biggest headache. And let's not forget about the STEM (science, technology, engineering, and mathematics) shortage.

"The government and the industry need to join hands and make sure young folks in schools learn the skills manufacturers need," says Professor Roper.

The impact of Brexit

Brexit – that's a big question mark. Nearly half of what British manufacturers sell goes to the European Union. If there's any trouble trading with them, it could be a problem for big companies and their supply chains. Plus, employers will need deeper pockets because the National Living Wage is going up every year. And we still haven't quite shaken off the low productivity hangover from the 2008 financial crisis.

But here's the good news: technology can help.

A glimpse into 2024 and beyond

Pioneering SME manufacturers

Results from NatWest's, Future Fit study reveal that 22% of SME manufacturers stand as leading pioneers. These forward-thinking leaders actively pursue growth opportunities, possess the internal capabilities to achieve them, and emphasise the formulation of strategies that harness disruptive possibilities, shaping their business outlook 5 to 15 years into the future.

These pioneering SMEs are strategically poised to embrace the ongoing technological revolution in the manufacturing sector. Often referred to as the "fourth industrial revolution" or Industry 4.0, this revolution revolves around the concept of "smart factories."

These factories integrate Internet of Things (IoT) sensors to enhance productivity. The World Economic Forum forecasts that by 2025, Industry 4.0 will generate up to £2.7 trillion of global value. Additionally, the integration of artificial intelligence (AI) alongside IoT sensors is anticipated to free up workers to concentrate on more creative tasks.

Technological advancements in UK manufacturing

As the world becomes increasingly interconnected and digitalized, manufacturers in the UK find themselves at the nexus of this technological evolution. The convergence of cutting-edge technologies is enabling manufacturers to drive their processes to new heights of efficiency, precision, and innovation.

Internet of Things (IoT)

The adoption of IoT sensors in "smart factories" permits extensive data tracking, simplifying production processes and streamlining supply chains. This technology represents a cornerstone of the "fourth industrial revolution."

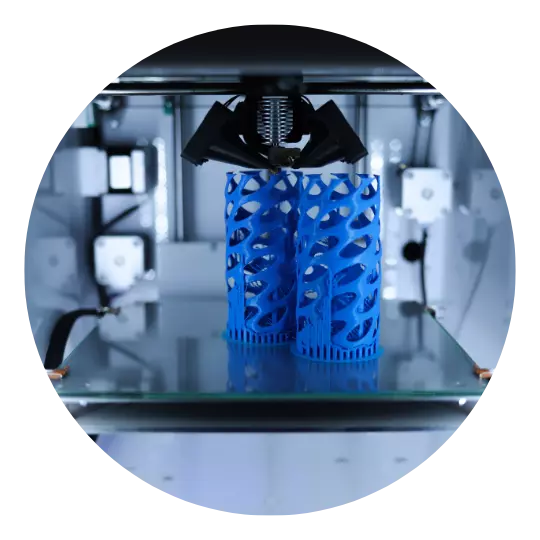

3D Printing

Numerous companies now employ 3D printing to expedite prototype development and even fabricate products, including artificial limbs, owing to the growing affordability of 3D printers.

AI & Machine Learning

Articial intelligence (AI) and machine learning applications can optimise factory operations by facilitating predictive maintenance, allowing for the early identification of irregularities and errors.

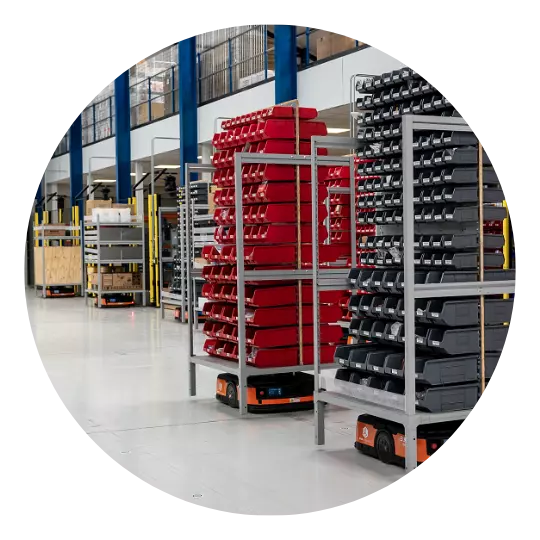

Automation

While automation is at times linked with job displacement, enterprises investing in robotics often reassign employees to more skilled roles. The IFR predicts that over 1.7 million industrial robots were installed globally by 2020.

The future of your manufacturing operation

These trends mirror a swiftly evolving manufacturing sector in the UK, driven by state-of-the-art technologies and inventive strategies.

In this dynamic landscape, innovation is the key to staying competitive and thriving in the ever-changing world of manufacturing. So, embrace the future of manufacturing and lead your industry by harnessing the capabilities of cutting-edge technology.